DTF Transfer Gang Sheets streamline custom apparel printing, but face challenges like misalignment and ink bleeding. Troubleshooting involves identifying issues (print quality, alignment), checking software/ink cartridges, maintaining printers, ensuring compatibility, using diagnostic tools, and seeking support from forums or specialists. Efficient management relies on documented steps for quick future reference.

DTF Transfer Gang Sheets are essential components in many industrial processes, ensuring efficient material handling. However, issues can arise, leading to disruptions and downtime. This comprehensive guide tackles common problems encountered in DTF transfer gang sheets, from misalignments causing uneven transfers to blockages hindering smooth operations. We’ll explore the root causes, offer troubleshooting strategies, and provide valuable tips to streamline your processes, maximizing efficiency with these critical systems.

- Understanding DTF Transfer Gang Sheets Basics

- Common Issues and Their Causes

- Effective Troubleshooting Strategies and Tips

Understanding DTF Transfer Gang Sheets Basics

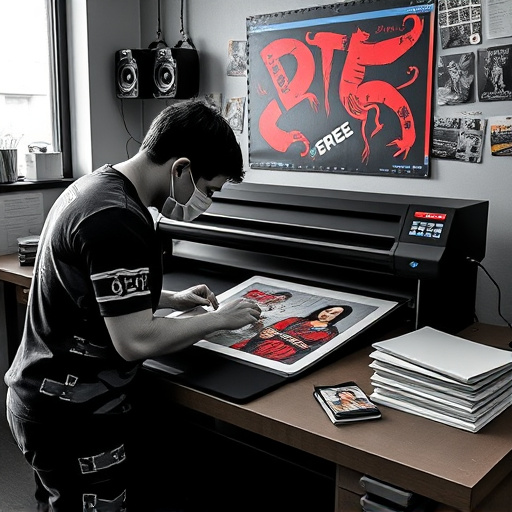

DTF Transfer Gang Sheets are a fundamental component in the process of custom apparel printing, especially when it comes to dtf printing for dark fabrics. These sheets are designed to facilitate the transfer of designs from a digital file directly onto fabric using heat and pressure. The term ‘gang’ refers to the multiple layers or colors that can be printed simultaneously on a single sheet, streamlining the production process. This method is particularly popular for creating personalized items like direct to film personalized hoodies, allowing for intricate and vibrant designs with ease.

By understanding the basics of DTF Transfer Gang Sheets, printers can efficiently troubleshoot common issues. The sheets consist of a backing material, a release agent, and the actual transfer film. Proper alignment and pressure during the printing process are crucial to ensure the design is accurately transferred onto the fabric. Any misalignment or inadequate pressure can lead to poor print quality. Additionally, using the correct dtf transfer film compatible with your printer and ink is essential for achieving optimal results.

Common Issues and Their Causes

Many challenges arise during the DTF Transfer Gang Sheets process, particularly in the apparel industry where precise and efficient printing is paramount. One frequent issue involves misalignment of designs on the fabric, often due to improper calibration of the printing machine or variations in fabric movement during the transfer process. Such misalignments can lead to logos or graphics appearing distorted or off-center on the final product, impacting the overall quality and brand image.

Another common problem is ink bleeding or smudging, especially with DTF for Apparel. This typically occurs when excessive pressure is applied during the heat press stage or if the fabric type isn’t suitable for DTF printing. In some cases, using incompatible inks or not pre-treating the fabric as recommended can also cause ink to bleed, resulting in a blurred or unappealing design. Identifying and addressing these issues promptly ensures high-quality logos DFT for clothing brands and maintains customer satisfaction.

Effective Troubleshooting Strategies and Tips

When troubleshooting issues with DTF Transfer Gang Sheets, a systematic approach is key. Start by identifying the specific problem, whether it’s print quality, misalignment, or missing data. Check for common errors like incorrect settings in your software, depleted ink cartridges, or blocked nozzles—simple fixes that often resolve initial glitches. Utilize built-in diagnostic tools within your printing software to pinpoint issues accurately.

Engage in regular maintenance practices such as cleaning the print heads and ensuring proper DTF transfer temperatures. Keep a consistent paper supply and verify compatibility with your DTF printer. For complex problems, consult user forums or seek support from manufacturer experts. Documenting troubleshooting steps and outcomes can also prove valuable for future reference, enhancing your efficiency in managing potential DTF printing challenges. Remember, persistence and methodical problem-solving are essential to mastering the art of DTF transfers.

DTF Transfer Gang Sheets are essential tools in modern printing processes, but they’re not immune to issues. By understanding the basics, identifying common problems, and employing effective troubleshooting strategies, you can minimize downtime and maximize efficiency. Remember, prompt action on minor glitches can prevent major disruptions later. Keep refining your process, stay vigilant, and continue to optimize your DTF Transfer Gang Sheets for superior printing outcomes.